美國 DeFelsko 膜厚計

|

|

品牌

|

圖片

|

型號及特點 /備註

|

|

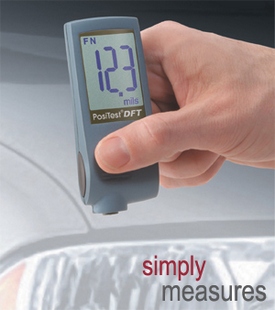

1.

|

DeFelsko

Coating Thickness Gage

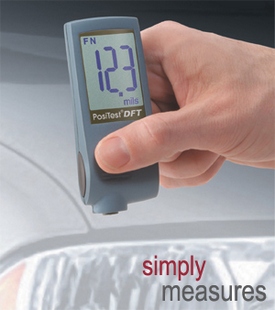

Model:

PosiTest DFT

美國制塗層測厚計

|

|

The PosiTest DFT Coating

Thickness Gage measures coatings on ALL metals. It is the economical

choice that retains the uncompromising quality of DeFelsko coating thickness and inspection

instruments.

Two

Models

- PosiTest DFT Ferrous

measures non-magnetic coatings on steel.

- PosiTest DFT Combo

measures both non-magnetic coatings on steel AND

non-conductive coatings on aluminum, brass, etc. Automatically

recognizes the substrate and takes a measurement.

Gauge Comes Complete

with:

- built-in probe

- wrist strap

- plastic shims

- hard shell storage case

- AAA battery

- instructions

- certificate of calibration traceable

to NIST.

Gauge Conforms to:

ISO 2178/2360/2808, prEN ISO 19840,

ASTM 244/B499/B659/D1186/D1400/D7091-05 E376/G12, BS3900-C5, SSPC-PA2

and others.

|

|

2.

|

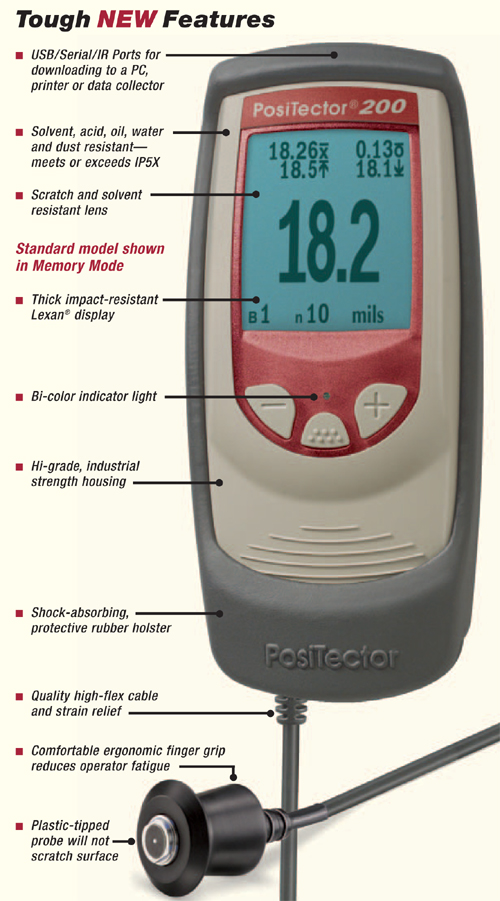

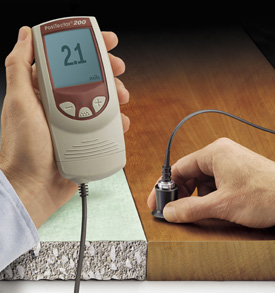

PosiTest 200 Series

|

|

|

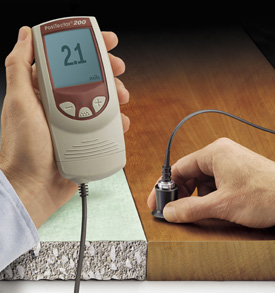

Overview:

Non-destructively measures a wide variety of applications using proven

ultrasound technology. Measures coating thickness over wood, concrete,

plastics, composites and more. Advanced models measure up to 3

individual layer thicknesses in a multi-layer system and features a

graphic readout for detailed analysis of the coating system. Proven

non-destructive ultrasonic technique conforms to ASTM D6132 and ISO

2808

and SSPC PA9 .

|

|

|

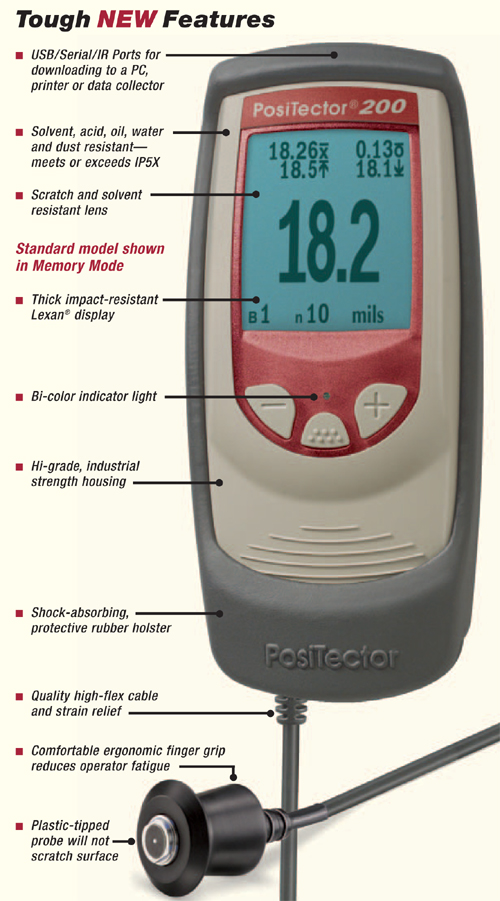

- Ready to measure - no

adjustment required to measure most coatings

- Menu-driven user interface

- One-Handed menu navigation

- Bi-color indicator light -

ideal in a noisy environment

- RESET feature instantly

restores factory settings

- Solvent, acid, oil, water and

dust resistant - meets or exceeds IP5X ingress protection

- Scratch/Solvent resistant

display suitable for harsh environments

- Shock-absorbing, protective

rubber holster with belt clip

- Two year warranty on both gage

body and probe

- Responsive transducers provide

fast, accurate readings (up to 40 readings/minute)

- Proven non-destructive

ultrasonic technique conforms to ASTM D6132 and ISO 2808 and SSPC PA9

- Certificate of Calibration

showing traceability to NIST included

- Continually displays/updates

average, standard deviation, and number of readings while measuring

- Internal memory stores up to

10,000 readings in up to 1000 batches

- Built-in clock to date and time

stamp each stored measurement

- USB, IR and serial output

options for simple communication with printers and PCs

- Backlit display for dim or dark

environments

- Mils/Microns switchable

- Selectable display languages

including English, Spanish, French, German, Portuguese, Chinese,

Japanese, Norwegian, Russian, Czech and Italian

|

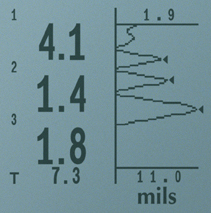

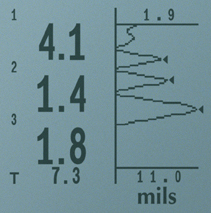

PosiTector

200 Model

|

B/Std |

B/Adv |

C/Std |

C/Adv |

| Measures

Total Thickness |

OK

|

OK

|

OK

|

OK

|

| Measures

Individual Layers |

|

OK

|

|

OK

|

| Graphical

Display |

|

OK

|

|

OK

|

| Typical

Applications |

Polymer coatings on

wood, plastic, composites, etc. |

Thicker coatings

on concrete, fiberglass, etc.

|

| Range* |

13 - 1000 microns

0.5 - 40 mils |

50

- 3800 microns

2 - 150 mils |

| Accuracy |

± (2 microns + 3% of reading)

± (0.1 mils + 3% of reading) |

|

Minimum Individual

Layer Thickness**

|

------- |

13 microns

0.5 mils |

------- |

50 microns

2 mils |

|

*Range limits apply to

polymer coatings only. **For multiple layer applications only.

Dependent on material being measured.

|

|

|

|

|

|

|

ORDERING

CHART

|

Our most

popular Built-in and Regular separate probe models

|

90°

Regular

probe for tight spots

|

Ideal for

anodized aluminum

|

Microprobes

- Our smallest probes for small parts or

hard-to-reach areas

|

Built-in and

Separate probes for thick protective coatings; epoxy, rubber,

intumescent fire proofing and more

|

|

F

E

R

R

O

U

S

|

|

Coatings on FERROUS

metals (Steel & Cast Iron)

|

|

Basic

Standard

Memory

|

F1

F2

F3

|

FS1

FS2

FS3

|

FRS1

FRS2

FRS3

|

|

F0S1

F0S2

F0S3

|

F45S1

F45S2

F45S3

|

F90S1

F90S2

F90S3

|

FT1

FT2

FT3

|

FTS1

FTS2

FTS3

|

FKS1

FKS2

FKS3

|

|

F

|

FS

|

FRS

|

|

F0S

|

F45S

|

F90S

|

FT

|

FTS

|

FKS

|

|

N

O

N

|

F

E

R

R

O

U

S

|

|

Coatings on NON-FERROUS

metals (Aluminum, Copper, etc.)

|

|

Basic

Standard

Memory

|

N1

N2

N3

|

NS1

NS2

NS3

|

NRS1

NRS2

NRS3

|

NAS1

NAS2

NAS3

|

NOS1

NOS2

NOS3

|

N45S1

N45S2

N45S3

|

N90S1

N90S2

N90S3

|

|

|

NKS1

NKS2

NKS3

|

|

N

|

NS

|

NRS

|

NAS

|

NOS

|

N45S

|

N90S

|

|

|

NKS

|

|

C

O

M

B

O

|

|

Combination ALL

METALS (Ferrous and Non-Ferrous)

|

|

Basic

Standard

Memory

|

FN1

FN2

FN3

|

FNS1

FNS2

FNS3

|

FNRS1

FNRS2

FNRS3

|

|

|

|

|

|

FNTS1

FNTS2

FNTS3

|

|

|

FNS

|

FNS

|

FNRS

|

|

|

|

|

|

FNTS

|

|

|

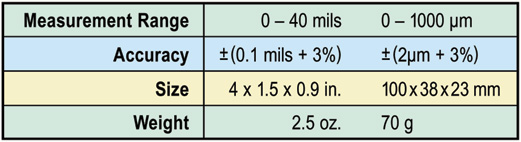

Measuring

Range

|

0 - 60 mils

|

Ferrous:

0 – 45 mils (0 – 1150 μm)

|

0 - 250 mils

|

0 - 500 mils

|

|

0 - 1500 um

|

Non-Ferrous:

0 – 25 mils (0 – 625 μm)

|

0 - 6 mm

|

0 - 13 mm

|

|

Accuracy**

|

+

(0.05 mils + 1%) 0 - 2 mils

+ (0.1 mils + 1%) > 2 mils

|

+

(0.02 mils + 1%) 0 - 4 mils

+ (0.1 mils + 3%) > 4 mils

|

+(

0.5 mils + 1%)

0 - 100 mils

+( 0.5 mils + 3%)

> 100 mils

|

+

(1 mil + 3%)

0 - 500 mils

|

|

+ (1

um + 1%) 0 - 50 um

+ (2 um + 1%) > 50 um

|

+(0.5

um + 1%) 0 - 100 um

+ (2 um + 3%) > 100 um

|

+

(0.01 mm + 1%) 0 - 2.5 mm

+( 0.01 mm + 3%) > 2.5 mm

|

+

(0.02 mm + 3%)

0 -13 mm

|

|

Matching

DeFelsko Calibration Standards

|

S1

A1

|

S2

A2

|

P1

|

P5

|

|

**Accuracies

are stated as a fixed value plus a percentage of the gage's actual

reading.

|

|

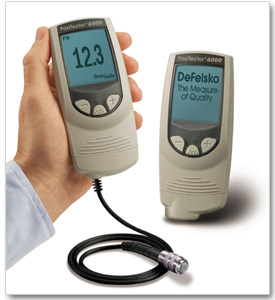

| Overview:

Rugged, fully electronic coating thickness gauges use magnetic and eddy

current principles to measure coating thickness on both ferrous

and non-ferrous metals, accurately and quickly. |

|

|

|

-

Ready to

measure-no calibration adjustment required for most applications

-

One-Handed menu

navigation

-

Bi-color

indicator light-ideal in a noisy environment

- RESET feature instantly

restores gauge to factory settings

- Solvent, acid, oil, water and

dust resistant-meets or exceeds IP5X ingress protection

- Wear-resistant probe tip

- Thick, impact and scratch

resistant Lexan® display suitable for harsh environments

- Protective rubber holster with

quick-release belt clip and probe storage

- Two (2) year warranty on gage

body and probe.

- Certificate of

Calibration showing traceability to NIST included

- Built-in temperature

compensation ensures measurement accuracy

- Hi-RES mode increases gages

displayed resolution for use on applications that require greater

precision

- Conforms to national and

international standards including ISO and ASTM

- Multiple calibration adjustment

options including 1 point, 2 point, known thickness and average zero

- Calibration Lock

- SSPC PA2 feature set determines

if film thickness over a large area conforms to user-specified min/max

levels (memory (3) gauges only)

- PSPC 90/10 feature determines

if a coating system complies with an IMO performance standard for

protective coatings (memory (3) gages only)

- Selectable display languages

- Flip Display for right-side-up

viewing

- Backlit display for dim or dark

environments

- Mils/Microns/mm switchable

- Extended cables available (up

to 250 ft/75 m) for remote measuring

- All Regular Separate Probes

suitable for underwater use

- All PosiTector 6000 Gauges are

available in your choice of Basic, Standard and Memory configurations

- Menu-driven user interface with

multilingual support including: English, Spanish, French, German,

Portuguese, Chinese, Japanese, Norwegian, Russian, Czech and Italian -

Gauge Screen Captures

- Select the Standard that

most closely matches the measuring range of your gage.

|

|

Order

Code

|

Ideal for |

Approximate

Thickness |

Coating/

Substrate

|

Accuracy

|

|

Block 1

|

Block 2

|

Block 3

|

Block 4

|

|

P1

|

PosiTector 6000

FT, FTS, NTS, FNTS

|

375 um

15mils

|

2 mm

80 mils

|

4.5 mm

185 mils

|

6.5 mm

250 mils

|

Polystyrene

Blocks

|

±(2.5 um + 0.05%

of thickness)

± {0.1 mil + 0.05%

of thickness)

|

|

P2

|

PosiTector 6000

FHS, NHS, EOC

|

2.5 mm

100mils

|

6.5 mm

250 mils

|

13 mm

500 mils

|

19 mm

750 mils

|

|

P3

|

PosiTector 100 C

|

375 um

15mils

|

1.5 mm

60 mils

|

2.5 mm

100 mils

|

4.5 mm

185 mils

|

|

P4

|

PosiTector 100 D

|

1.5 mm

60mils

|

2.5 mm

100 mils

|

4.5 mm

185 mils

|

6.5 mm

250 mils

|

|

P5

|

PosiTector 6000

FKS, NKS

|

1.5 mm

60 mils

|

2.5 mm

100 mils

|

6.5 mm

250 mils

|

12 mm

480 mils

|

|

P6

|

PosiTector 200 C

|

375 um

15 mils

|

1.5 mm

60 mils

|

2.5 mm

100 mils

|

3 mm

125 mils

|

|

All certified standards

are supplied with a Certificate of Calibration traceable to NIST or PTB.

Polystyrene Blocks: (38 x 70

mm (1.5" x 2.75")

|

|

|

|

|

|